Precision Control for Efficient Boiler Operation

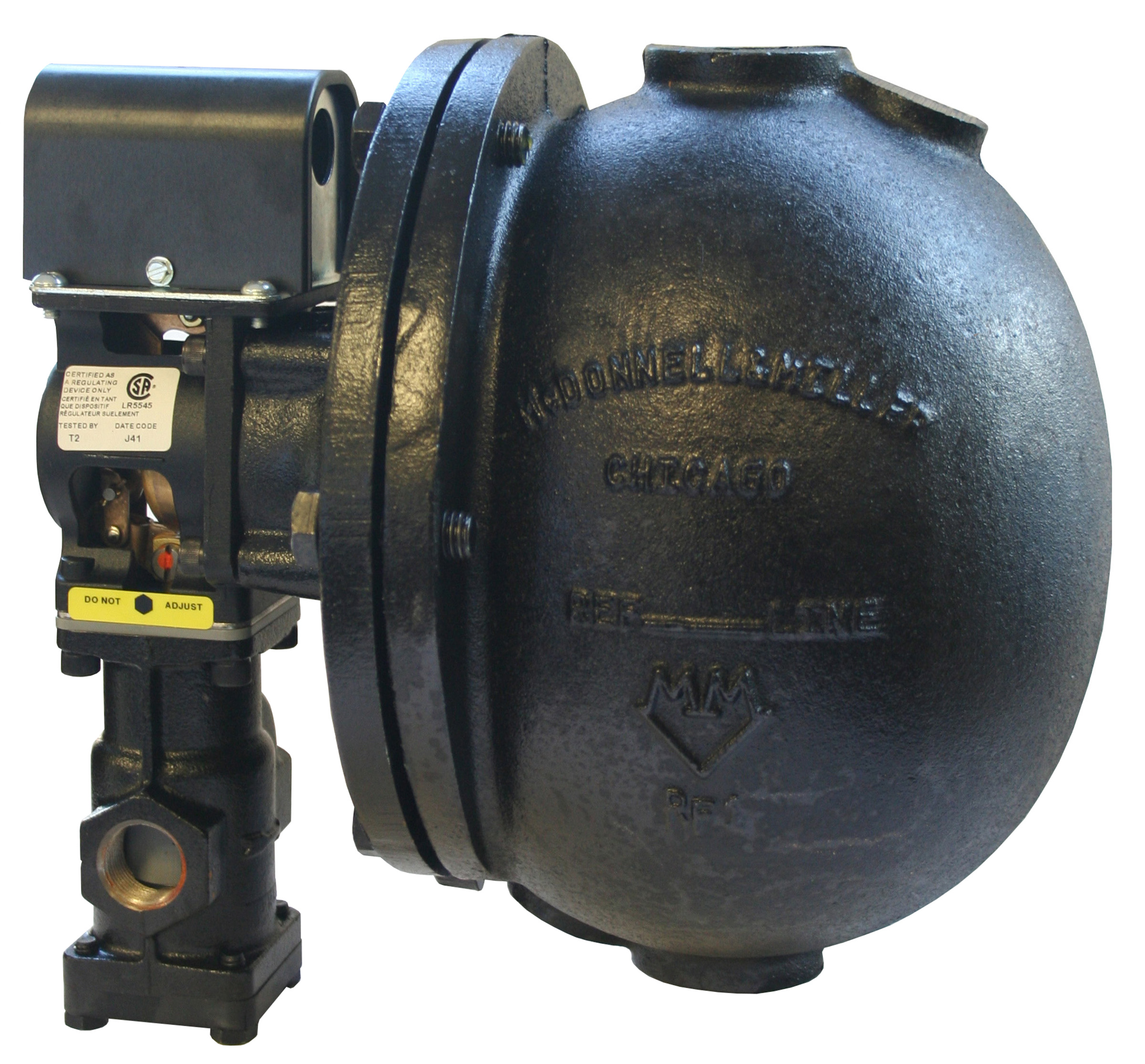

McDonnell & Miller, a unit of ITT Industries, is a leader in engineering and manufacturing boiler controls, liquid level controls, low-water cutoffs, and flow switches for steam and hot water boilers in industrial, commercial, and building trade applications.

Key Features:

- Automatic Shut-Off: Prevents boiler damage and enhances safety.

- High Precision: Ensures accurate water level and pressure control.

- Robust Design: Durable construction suitable for harsh industrial conditions.

Specializations:

- Boiler Controls: Advanced engineering for reliable boiler operation.

- Power Switches: Precision controls for optimal performance.

- Low-Water Cutoffs: Available in float-operated or probe and float built-in styles for reliable boiler feed pump control.

Benefits:

- Enhanced Efficiency: Maximizes boiler performance through precise control.

- Reduced Maintenance: Reliable operation minimizes downtime and maintenance.

- Standards Compliance: Adheres to industry safety and performance standards.

Applications:

- Commercial boilers

- Industrial boilers

- Steam and hot water systems

Low-Water Cutoffs:

- Operation: Mounted at the boiler water line to start and stop the pump as needed.

- Efficiency: Maintains boiler water level within recommended limits for maximum steaming efficiency.

Pump Controls:

- Versatility: Available for low or high-pressure boiler applications.

- Types: Float-operated pump controllers with snap action switches, single pole single throw switches, and single pole double throw switches.

- Features: Magnetic repulsion operation for dependable performance at higher pressures.

Invest in McDonnell & Miller controls to ensure your boiler systems run safely, efficiently, and reliably.