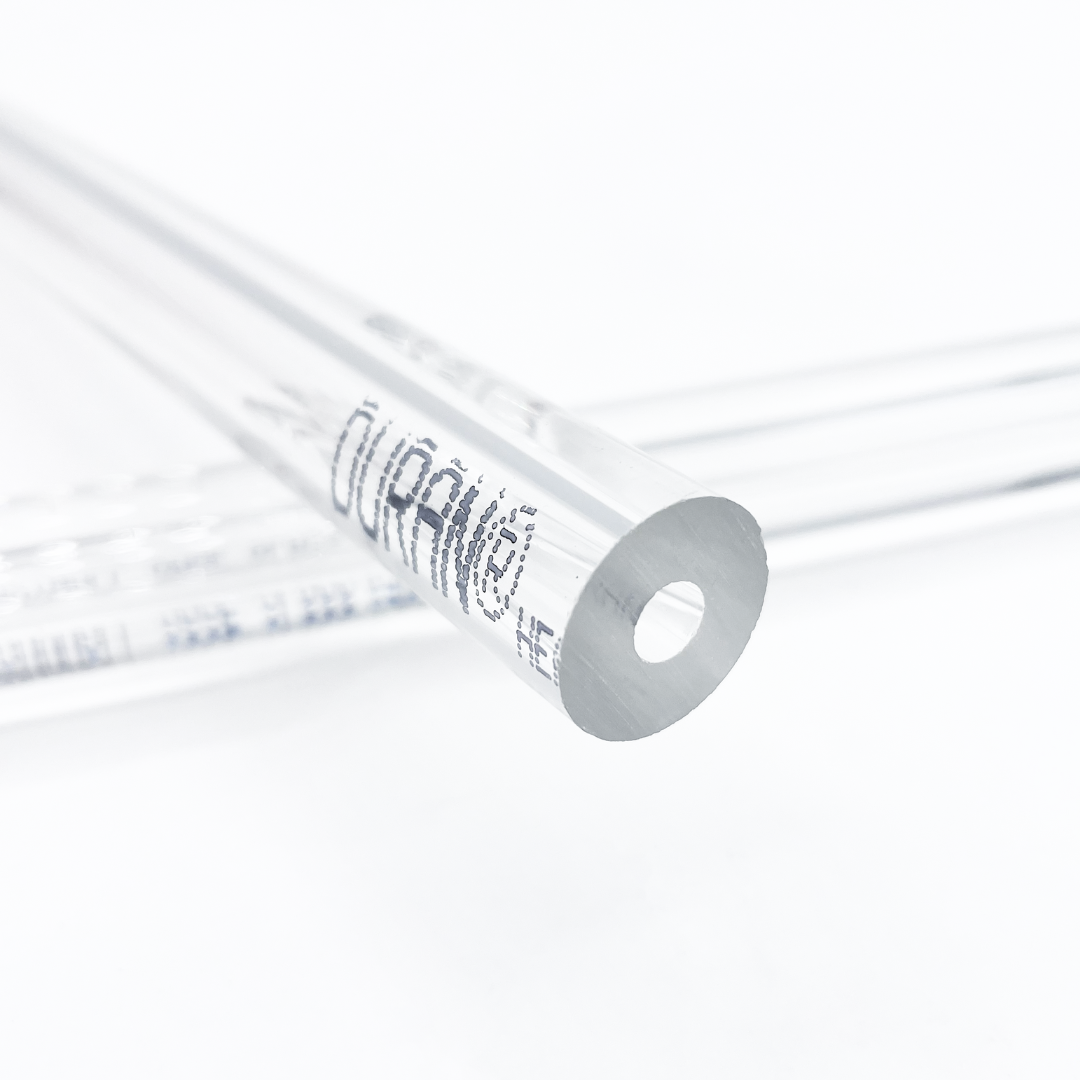

- Annealed Borosilicate (Clear): For general service up to 446°F (230°C). Use 1/4" or thicker glass; max 150°F temperature differential.

- Tempered Borosilicate (Clear): Handles up to 500°F (260°C) and higher pressure than annealed. Not for corrosive or extreme thermal shock environments.

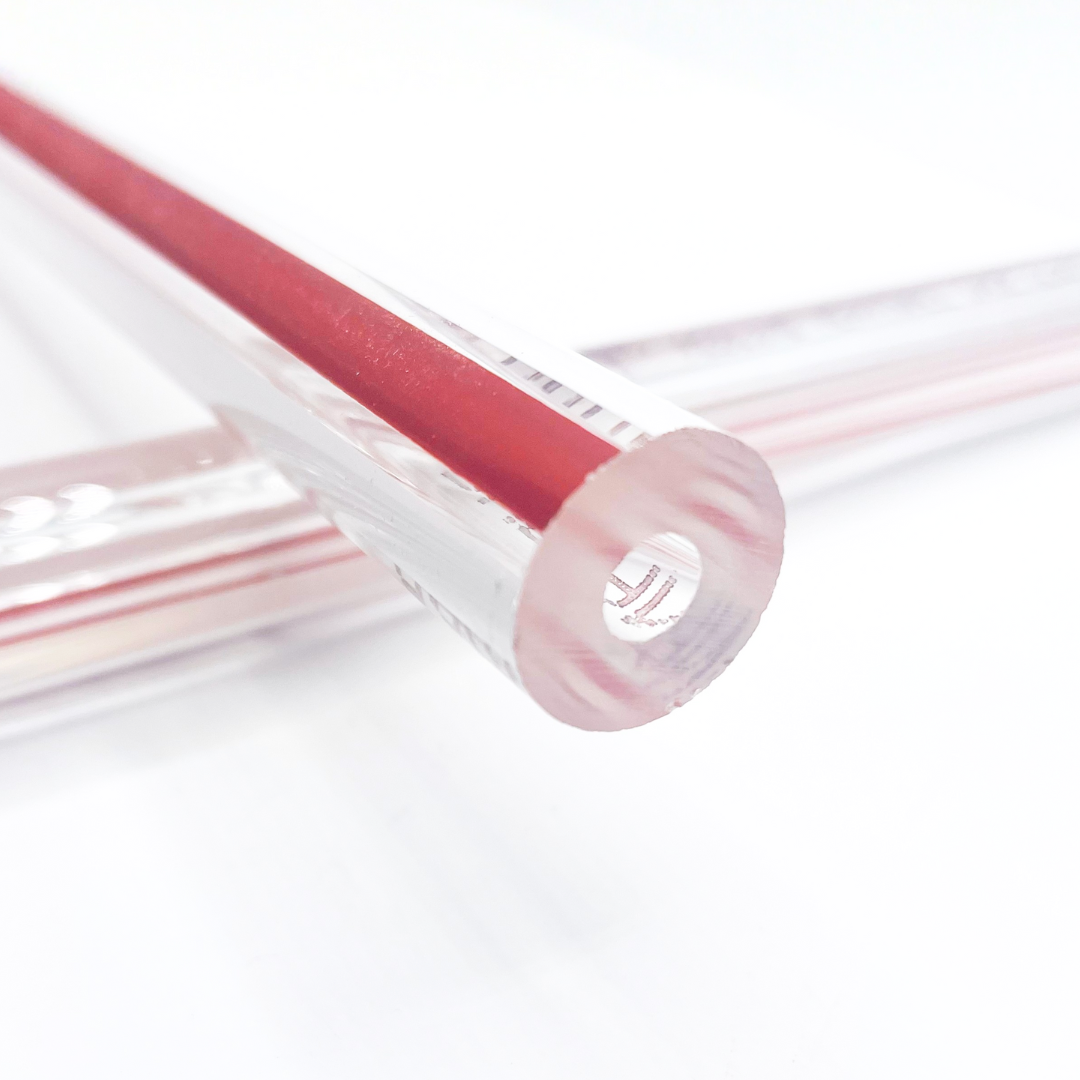

- Cobalt Blue Borosilicate (Blue): Reduces glare for clear flame, smoke, and ash observation in boilers and furnaces. Up to 1/4" thick.

- Fused Quartz (Clear): Ideal for labs and high-temp industrial use; continuous operation up to 1742°F (950°C). Optical grade available on request.

Applications: Furnaces, ovens, observation ports, flow indicators, pressure vessels, and tanks.

Tempering Benefits: Enhances strength, scratch resistance, and thermal shock durability.

Shipping: Standard lead time 5–7 days; expedited options available.

Minimum Order: $25.00